THE SPECTRAL ANALYSER – ONE OF THE CORE PIECES OF EQUIPMENT AT OUR COMPANY.

Alongside our experience and the trained eyes of our employees, the spectrometer is our most important tool for distinguishing between the different grades of aluminium. But how does this equipment work? It is easy to explain how this type of spectrometer works. Electricity is supplied to the metal samples. The resulting spark is guided onto a reflective grille. The light is then split into wavelengths (colours, similar to a rainbow). As every element produces a different colour when exposed to electricity, phototubes at the end of the spectral arc measure the intensity of the relevant colour and calculate its concentration in the ppm range (1 part per million = 10-6 = parts per million = 0.0001 %).

As these evaluations are used as the basis for our contracts, it is not surprising that we invest a lot of money every year in the servicing of our analysis equipment and their recalibration to the original factory state.

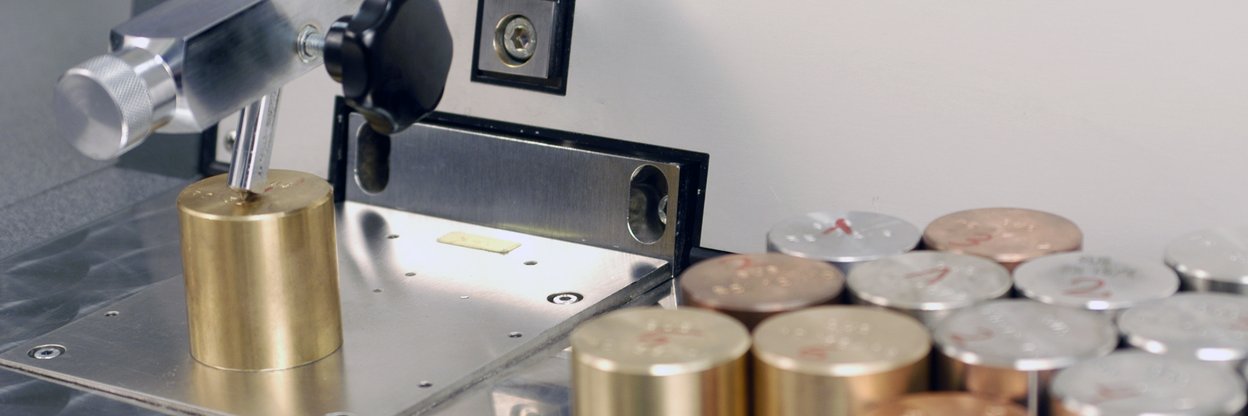

For this purpose, the LAB S and Spectro Test spectrometers are stripped down to their individual parts and the hardware and software are precisely examined and maintained. This is necessary because the wave conductors become increasingly weaker and the phototubes lose power over time. Dust particles and other contamination also have to be removed. The maintenance work takes one week to complete and can only be carried out by specialists. When the maintenance work is complete, special samples are tested and compared to international standards.

If there are no deviations, the spectrometer is considered to be as good as new again and ready to be placed back into operation.

To enable an international comparison of the values from our analyses, we participate every year in interlaboratory tests organised by the German Association of the Aluminium Recycling Industry. Cast aluminium alloys are specially produced for this purpose and then analysed by numerous companies both at home and abroad. An average value is determined based on the submitted analyses. This process allows us to confirm that our analyses do not display any incorrect deviations and also demonstrates how precisely we determine and guarantee the quality levels of our aluminium.